01 - Coordination Project

Summary

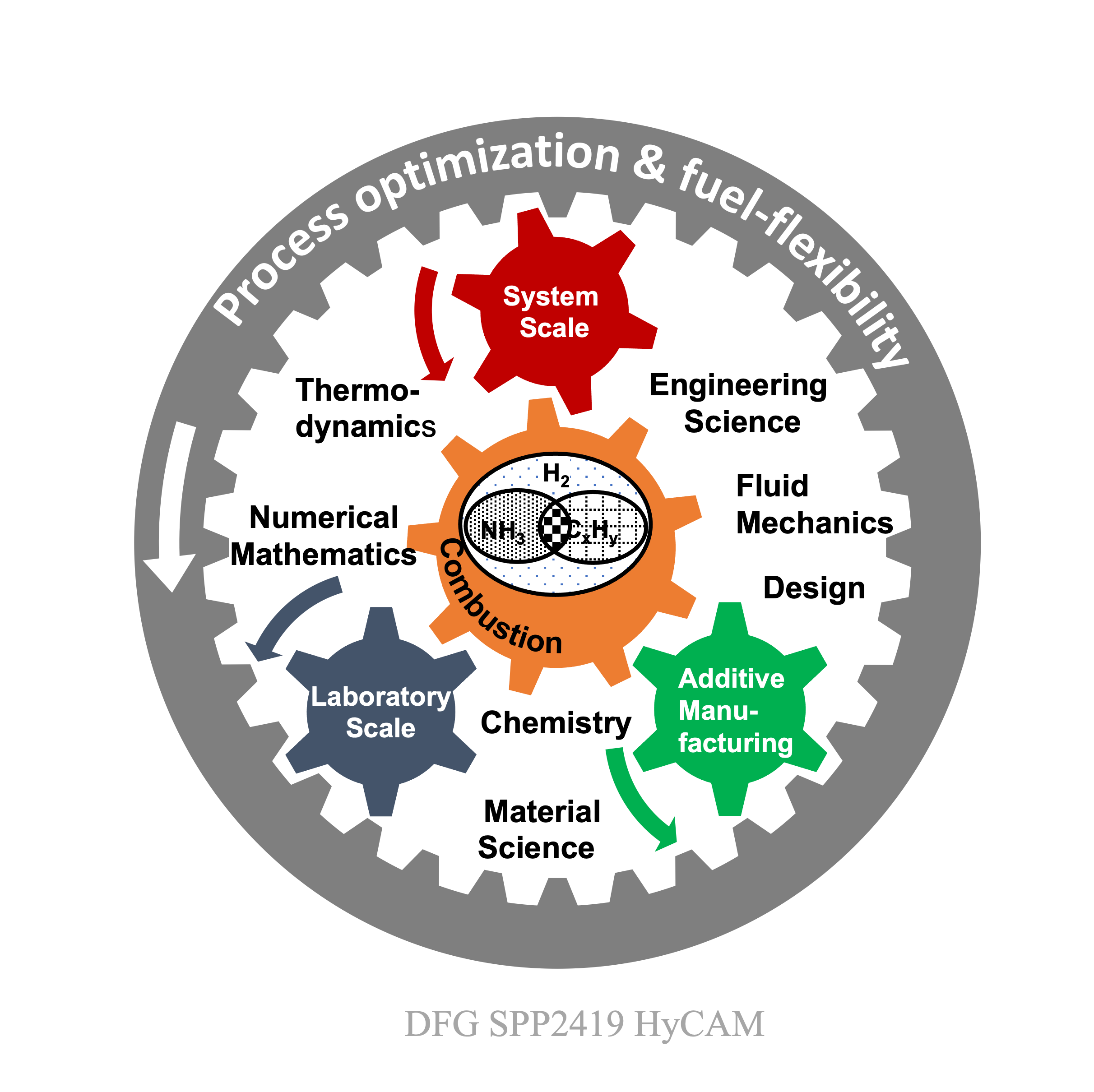

DFG SPP2419 HyCAM, employing a highly interdisciplinary approach, endeavours to facilitate collaboration across various disciplines, encompassing chemistry, combustion science, and additive manufacturing. The goal is to achieve a knowledge-based and efficient design process for optimizing hydrogen-based fuel combustion while accounting for manufacturing constraints. This Priority Program (PP) posits that the simultaneous enhancement of flexibility, efficiency and emission control in thermochemical energy conversion processes can be achieved only via a comprehensive understanding of combustion fundamentals while integrating modern 3D manufacturing processes with simulation-based design and strategic utilization of Additive Manufacturing (AM) suitable materials.

For structuring the pertinent research fields, it is important to establish the necessary connections between combustion science and AM while simultaneously delving into the fundamental inquiries within each discipline. Thermochemical energy conversion processes occur across extensive length and time scales spanning multiple orders of magnitude and require investigation at both laboratory and system scales. On the other hand, for additive manufacturing, focal points include burner and combustion chamber design (e.g., topology optimization), sensor integration and meticulous selection of materials. Additive manufacturing holds significant potential to contribute to all areas of combustion to be investigated. Specifically, on the laboratory scale, AM facilitates the creation of intricate burners and combustion chambers, hence enabling experimental investigations which were previously unattainable. Moreover, it also aids in scaling up the knowledge from lab-scale to system-scale applications to enable the development of fuel-flexible and scalable industrial burners and gas turbines.

The attained goals of this PP are to develop domain-specific knowledge and methods, foster interdisciplinary collaboration between combustion science and manufacturing, and validate approaches both experimentally and numerically. Specific objectives include advancing methods for designing complex additive manufacturing burner and combustion chamber concepts and integrating numerical and experimental analysis. The focus is on bridging combustion science and advanced manufacturing, particularly in the thermochemical conversion of hydrogen-containing fuels. In this framework, proactive coordination is crucial in leveraging synergies within the priority program and accomplishing its scientific objectives. The coordination project seeks to advance Research Data Management (RDM) practices and facilitate the dissemination of research findings, fostering collaboration and knowledge exchange within DFG SPP2419 HyCAM. Additionally, this Priority Program aims to promote and train early-career researchers by utilizing the network’s resources effectively, including regular project workshops and specialized sessions for young researchers.

Members

Prof. Dr.-Ing. Heinz Pitsch

Coordinator

RWTH Aachen University

Institute for Combustion Technology

h.pitsch(at)itv.rwth-aachen.de