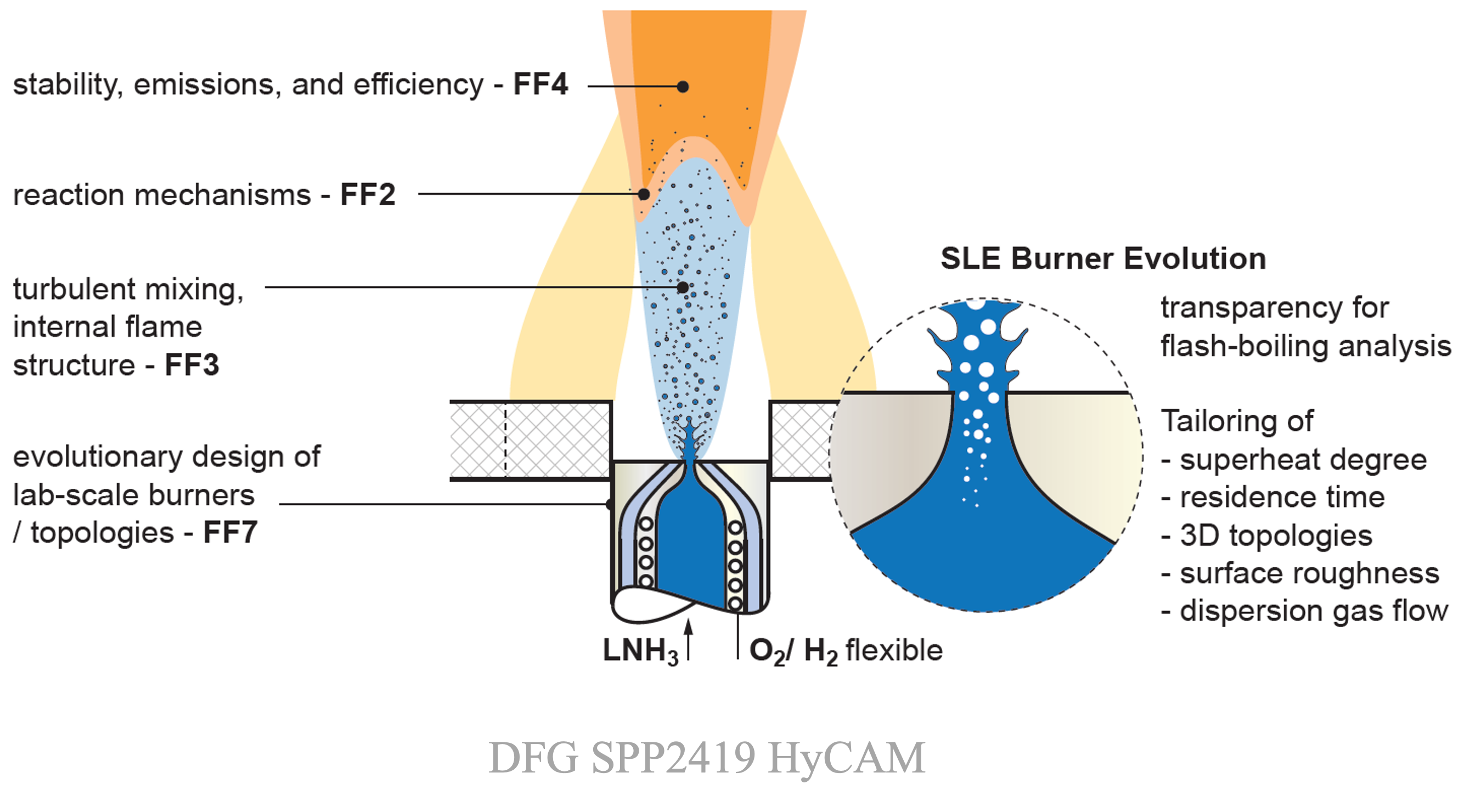

11 - SLE4Flame – Spray-burner development via selective laser-induced etching for flash-boiling assisted combustion of liquid ammonia

Summary

In this joint project, the applicants are pursuing a novel concept for a hybrid burner nozzle design to advance the vision of liquid ammonia combustion in stable spray-flames. The innovative design combines two mechanisms for atomization, i.e. pressurized and dispersion-gas atomization, to obtain efficient stable combustion with carbon-free fuels. The keys for the realization of this concept and for overcoming the associated scientific challenges are the subtractive manufacturing process ‘Selective Laser-induced Etching’ (SLE) and the fundamental understanding of atomization and flame processes for superheated liquefied ammonia. Only SLE is capable of producing the underlying complex three-dimensional flow topology with unsurpassed accuracy and defined surface roughness. At the same time, due to ist transparent design, it provides the basis for a first-time simultaneous nozzle-internal and nozzle-external experimental analysis of physical sub-processes involved. New insights achieved in this way will be incorporated into the development of high-fidelity models of the entire spray-flame process. In this context, flash-boiling is identified as the crucial process to be investigated and understood by taking into account the entire process chain inside and outside the nozzle.

Research Team

Univ.-Prof. Dr.-Ing. Reinhold Kneer

Principal Investigator (PI)

RWTH Aachen University

Institute of Heat and Mass Transfer

kneer(at)wsa.rwth-aachen

Dr.-Ing. Manuel Armin Reddemann

Principal Investigator (PI)

RWTH Aachen University

Institute of Heat and Mass Transfer

reddemann(at)wsa.rwth-aachen.de

Univ.-Prof. Dr. Wilko Rohlfs

Principal Investigator (PI)

RWTH Aachen University

Institute of Heat and Mass Transfer

rolhfs(at)wsa.rwth-aachen

Univ.-Prof. Dr.-Constantin Häfner

Principal Investigator (PI)

RWTH Aachen University

Chair for Laser Technology

constantin.haefner(at)ilt.fraunhofer.de

Prof. Dr.-Ing. Heinz Pitsch

Principal Investigator (PI)

RWTH Aachen University

Institute for Combustion Technology

h.pitsch(at)itv.rwth-aachen.de

Christian Hinke

Researcher

RWTH Aachen University

Chair for Laser Technology

christian.hinke(at)llt.rwth-aachen.de

Peter Augustin M.Sc.

Doctoral Researcher

RWTH Aachen University

Institute of Heat and Mass Transfer

augustin(at)wsa.rwth-aachen.de

Fabian Fröde

Doctoral Researcher

RWTH Aachen University

Institute for Combustion Technology

f.froede(at)itv.rwth-aachen.de

Henry Axt

Doctoral Researcher

RWTH Aachen University

Chair for Laser Technology

henry.axt(at)llt.rwth-aachen.de