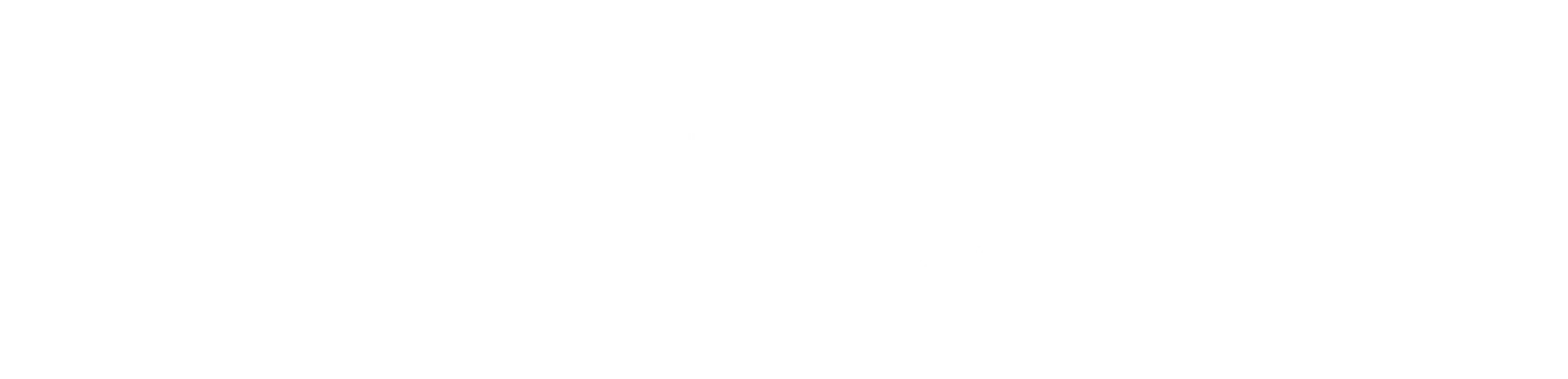

04 - Development and Application of a Simulation-Based Design Process for Fuel-Flexible Burners using Additive Manufacturing

Summary

For the transformation towards future sustainable energy systems, fuel-flexible burners are urgently needed to cope with the gradual transition from natural gas to fully hydrogen-fueled operation. Significant challenges exist for the development of such burners in the areas of flame stability and flashback, emissions, and mixture formation, as hydrogen-based fuels have fundamentally different combustion properties compared to conventional fuels. The ultimate objective of this proposal is to enable the design of industrial burner systems with special emphasis on robust and efficient operation with different hydrogen/methane blends while ensuring manufacturability and safety. In the proposed work, these challenges will be tackled by combining model development and a simulation-based design process with experimental investigations and innovative additive manufacturing (AM). The latter allows for a large degree of freedom in design needed to create compact, flexible, and intrinsically stable burners. In this project, an inverse design process will be developed and, as a demonstration, applied to optimize an industrial multi-jet burner with respect to specific target quantities including flame properties, such as stability (flame flashback and blow-off) and emissions (NOx, CO), as well as design parameters, such as internal pressure loss and heat resistance. One challenge is the need for accurate and cost-efficient simulation techniques for hydrogen-based fuels, which will be developed as part of the project. This comprises Reynolds-averaged Navier Stokes (RANS) simulations, which will be improved in predictiveness by applying data assimilation based on the Ensemble Kalman Filter using results from large-eddy simulations and experimental data. The experiment provides consumption speeds and properties of turbulent flames necessary to include effects of thermodiffusive instabilities in the RANS model. The assimilated RANS model will then be applied to optimize the burner geometry and operating strategies using adjoint sensitivities while considering design constraints imposed by AM. The design process will be facilitated by AM using parametric models of the burner. Further developments will be made to improve the quality of AM-fabricated burners, which includes optimizations regarding thin walls, filigree features, and achievable overhang angles especially for high-temperature resistant materials. The strongly interdisciplinary approach including combustion engineering and AM in this proposal will enable the methodological framework for a simulation-based design process of fuel-flexible industrial burners.

Research Team

Prof. Dr.-Ing. Heinz Pitsch

Principal Investigator (PI)

RWTH Aachen University

Institute for Combustion Technology

h.pitsch(at)itv.rwth-aachen.de

![[:en]Schleifenbaum[:] [:en]Schleifenbaum[:]](https://spp2419.rwth-aachen.de/wp-content/uploads/2024/03/Schleifenbaum-e1713624919894.jpg)

Prof. Dr. Johannes H. Schleifenbaum

Principal Investigator (PI)

RWTH Aachen University

Digital Additive Production Chair

johannes.henrich. schleifbaum(at)dap.rwth-aachen.de

Dr.-Ing. Joachim Beeckmann

Principal Investigator (PI)

RWTH Aachen University

Institute for Combustion Technology

j.beeckmann(at)itv.rwth-aachen.de

Dr.-Ing. Michael Gauding

Senior Researcher

RWTH Aachen University

Institute for Combustion Technology

m.gauding(at)itv.rwth-aachen.de

Yannick Heising

Doctoral Researcher

RWTH Aachen University

Digital Additive Production Chair

yannick.heising(at)dap.rwth-aachen.de

Florence Cameron

Doctoral Researcher

RWTH Aachen University

Institute for Combustion Technology

f.cameron(at)itv.rwth-aachen.de

Johannes Willkomm

Doctoral Researcher

RWTH Aachen University

Digital Additive Production Chair

johannes.willkomm(at)dap.rwth-aachen.de

Luca Juris

Doctoral Researcher

RWTH Aachen University

Digital Additive Production Chair

luca.juris(at)dap.rwth-aachen.de