05 - Development of an additively manufactured research burner for increased energy efficiency

Summary

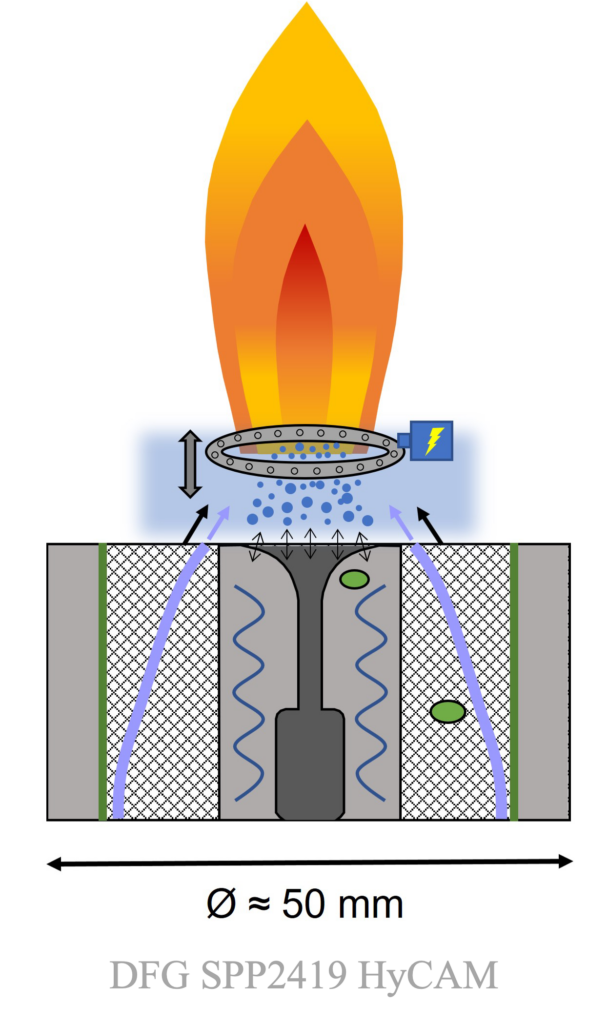

In view of global warming, carbon-free energy sources are of utmost importance for the reduction of CO2 emissions into the atmosphere. This requirement affects the transportation sector, aviation systems, industry, and private households, where the transportation sector contributes about 20 % to the worldwide CO2 emissions. Alternatives to carbon-containing hydrocarbons and alcohols are ammonia (NH3) and/or hydrogen (H2), both of which are carbon free. However, these species have different disadvantages. Ammonia contains nitrogen, which causes the emission of NOx, and hydrogen is highly reactive, causing safety issues, and it has a low energy content. Thus, a combination of these fuels, or their addition to either conventional or synthetic fuels, may be a big step towards the use of carbon-reduced or even carbon-free energy sources. The use of additive manufacturing (AM) offers a promising approach due to the high degree of design freedom and the possibility to realize complex (internal) geometries with materials such as the nickel base alloy MAR-M247, which can hardly be processed with conventional manufacturing techniques. Furthermore, the potential to integrate sensors is a strong support for the research in this field. The present project focuses on the addition of ammonia and/or hydrogen to liquid biofuels, such as methanol, ethanol, or n-butanol, to improve their combustion characteristics. The carbon-free fuels may be injected as gases or liquids (at reduced temperatures) or dissolved in the liquid fuels. The latter method requires knowledge of the solubility of hydrogen and ammonia in biofuels, as well as the breakup and evaporation characteristics of these liquids. A combined effort of numerical modeling, simulations, and experimental studies of the near-injector processes as well as contributions from additively manufactured burner technology ensure an excellent gain in knowledge to reduce global warming by ultimately carbon-free energy and transportation sectors.

Research Team

![[:de]Sehrt[:] [:de]Sehrt[:]](https://spp2419.rwth-aachen.de/wp-content/uploads/2024/03/Sehrt.png)

Prof. Dr.-Ing. Jan T. Sehrt

Principal Investigator (PI)

Ruhr University Bochum

Chair of Hybrid Additive Manufacturing

jan.sehrt(at)ruhr-uni-bochum.de

Prof. Dr. rer. nat. Eva Gutheil

Principal Investigator (PI)

Heidelberg University

Interdisciplinary Center for Scientific Computing

gutheil(at)iwr.uni-heidelberg.de

Prof. Dr.-Ing. Günter Brenn

Principal Investigator (PI)

Graz University of Technology

Institute of Fluid Mechanics and Heat Transfer

guenter.brenn(at)tugraz.at

![[:de]Kretzer[:] [:de]Kretzer[:]](https://spp2419.rwth-aachen.de/wp-content/uploads/2024/03/Kretzer.png)

Nele Kretzer

Doctoral Researcher

Ruhr University Bochum

Chair of Hybrid Additive Manufacturing

nele.kretzer(at)ruhr-uni-bochum.de

![[:de]Singh[:] [:de]Singh[:]](https://spp2419.rwth-aachen.de/wp-content/uploads/2024/03/Singh.jpg)

Chandra Prakash Singh

Doctoral Researcher

Heidelberg University Interdisciplinary Center for Scientific Computing

chandra.singh(at)iwr.uni-heidelberg.de

![[:de]Wan[:] [:de]Wan[:]](https://spp2419.rwth-aachen.de/wp-content/uploads/2024/03/Wan.png)

Jiawei Wan

Doctoral Researcher

Heidelberg University Interdisciplinary Center for Scientific Computing

jiawei.wan(at)iwr.uni-heidelberg.de

![[:de]Morse[:] [:de]Morse[:]](https://spp2419.rwth-aachen.de/wp-content/uploads/2024/03/Morse.jpg)

Kristen Morse

Doctoral Researcher

Graz University of Technology

Institute of Fluid Mechanics and Heat Transfer

kristen.morse(at)tugraz.at